- precise material removal and modification

- Laser ablation, micromachining, and laser-induced breakdown spectroscopy (LIBS)

- Electronics fabrication, medical device manufacturing, surface texturing

Introduction

In the last years, numerous materials processing techniques have been revolutionized by the non-tactile nature of laser beams. This includes welding, cutting, drilling, ablation, surface structuring, perforation and alike techniques.

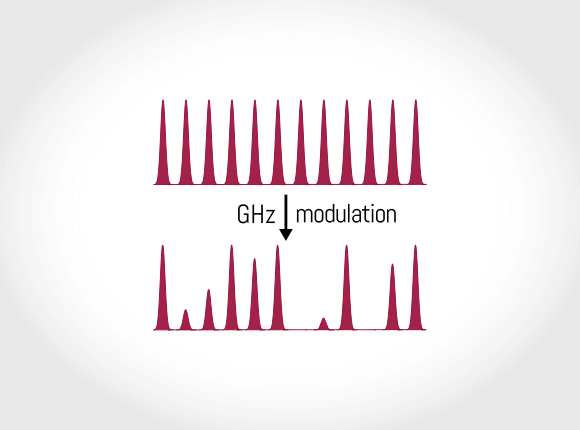

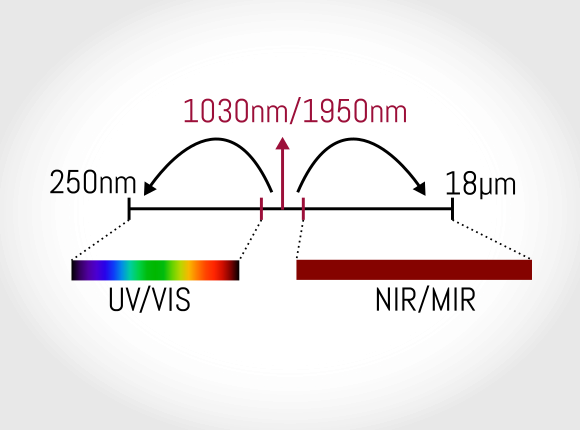

Many of these applications benefit from the use of femtosecond lasers which allows materials processing of practically any material with outstanding precision and minimal collateral damage. The improvements in the morphology of the processed material by using femtosecond pulses rather than nanosecond pulses has been studied in numerous publications [1-3]. Often the morphology can further be improved by utilizing flexible laser bursts [4], which can be produced by a patented technology of AFS. Furthermore, access to different wavelengths ranging from the XUV, 343nm over 515nm, 1030nm and 1950nm all the way to the Mid-IR enables efficient, high-quality processing of all kinds of materials.

Suitable products

References

[1] B. N. Chichkov et al. „Femtosecond, picosecond and nanosecond laser ablation of solids“ Appl. Phys. A Mater. Sci. Process. 63, 109–115 (1996).

[2] Stuart et al. „Nanosecond-to-femtosecond laser-induced breakdown in dielectrics“ Phys. Rev. B 4, 1749–1761 (1996).

[3] A. Kanitz et al. „Review on experimental and theoretical investigations of the early stage, femtoseconds to microseconds processes during laser ablation in liquid-phase for the synthesis of colloidal nanoparticles„, Plasma Sources Sci. Technol. 10, 103001 (2019).

[4] C. Kerse et al. „Ablation-cooled material removal with ultrafast bursts of pulses“ Nature 537, 84–88 (2016).